|

Designed

and built in USA

- Purchase

turnkey systems or controls

- Joystick

or digital handwheel

- Contouring

or positioning in one-to-four axes

- Total

remote operation from a personal computer

- Interfaced

to PC and CAD/CAM packages

- Two year

warranty, self diagnostics, and built in user-programmable calculator

More

than 450 of these CNCs are now installed throughout the USA!

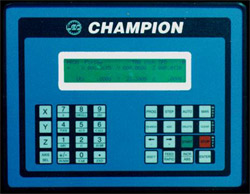

Hardware

Specifications:

One

to Four axes of CNC control

Sealed faceplate

Tactile feel pressure keyboard

Alpha-numeric display

Modes displayed:

..........Tool number

..........Instantaneous vector speed display

..........Actual position displays

..........User variable displays

2000+ memory locations

Closed loop positioning

RS232 input and output

Continuous Path machining

8 optically coupled inputs

16 optically coupled outputs

4 counter inputs (Quadrature or Pulsed)

4 analog inputs and outputs, user programmable

Input encoder - ANY RESOLUTION

Programmable in inches, MM, degrees, etc.

Battery backup for 30 days

|

Network

Specifications

RS232

Input and Output

255 Champions on one Personal Computer

Baud rate selectable up to 19.2K

Error correction by retransmission

Any Champion data can be sent on command

Message length 4 to 264 characters long

Broadcast to all Champions

Handshaking, including CRC

Electrical Specifications

Voltage - 120 or 240 VAC +/-15%

Power - 30 Watts

Physical Specifications

Size - 12.2" x 9.5" x 4.75"

Mounting - 4 ea. Nuts for #8 screws

Program

Specifications:

User programmable software commands

Keyboard lockout

Custom displays

Programmable calculator commands

Floating point calculations

Variables (storage registers 100+)

Dwells from .1 to 999.9 sec, or infinite

DO loops 1 to forever (unlimited nesting)

Subroutines, unlimited nesting

Calls

G codes (canned cycles)

Aux codes

Software limits

.............Machine zero

.............Swap any set of axes

.............Servo gains

.............Control user displays

.............Mirror image any axis

.............Scaling any factor any axis combination

.............Multiple absolute zeros

.............Tool offsets 64+ (expandable)

.............Tool diameter compensation

.............Max feed velocity variable

Linear moves

Circular moves (any two or three axes)

Inch/mm conversion

Incremental./absolute programming

Feed rate 0 up to 200% (customer limited)

Debugging testing aids

Rectangular or polar programming

Mold rotation

Conical cavity milling

Conical radial milling

Plane rotation

Printout of user programs

Cross reference of user variables

Cross reference of user subroutine

Digitizing

|